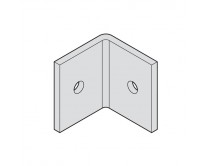

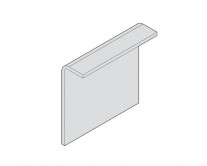

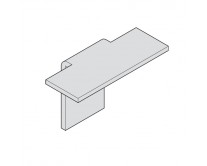

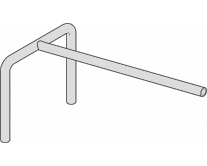

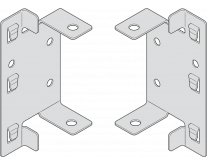

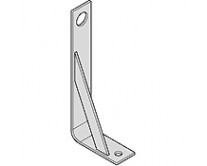

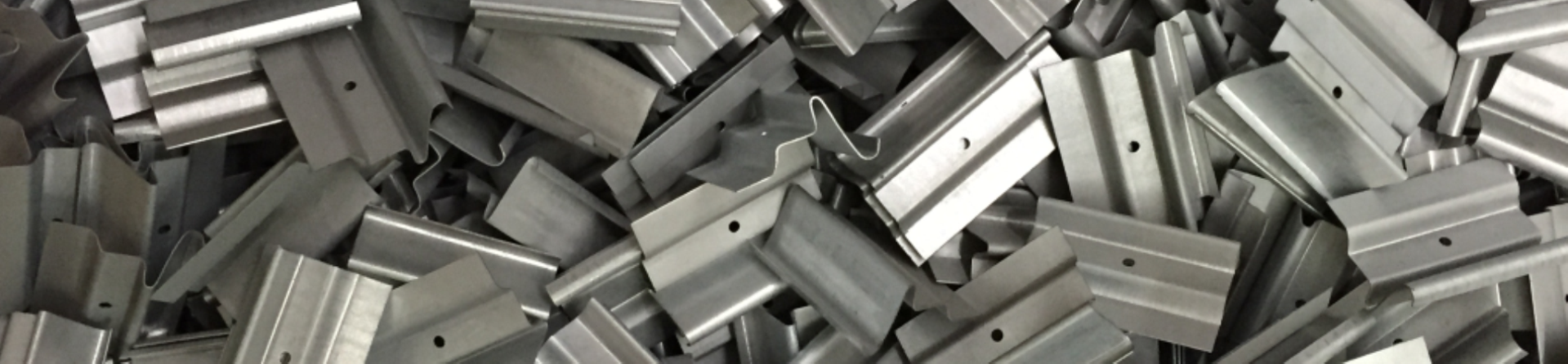

Stampings

Our day-to-day activities include the development and manufacture of custom-built products.

We’ll provide the service you require:

- technical advice + development

- technical drawing + 3D-CAD construction

- tool making + prototype assembly

- production + surface finishing/refinement

Customer requirements vary a great deal according to sector and application, so that we have geared our production capabilities in stamped/punched parts and sheet metal/shaped products accordingly. We work material from 0.3 mm to 14 mm thick and up to 350mm wide.

The raw materials involved here are steel, high-grade steel, copper, aluminium, non-ferrous metals (suitable for stamping) in the required compositions and quality.

Besides stamping, bending/shaping and punching we have many more processing possibilities such as thread-cutting, riveting, spot welding, shielded arc welding and assembly/installation.

Naturally, we also provide final surface finishing/refinement ‑ such as hot-dip galvanising in our highly modern hot-dip galvanising plant ‑ and all other standard surface finishing including the necessary pre-treatment.

We would be very pleased to support you with all your individual questions and suggestions regarding WUS.

Give us a ring or leave a message indicating the information you need.

We will contact you as quickly as possible.

Your WUS team